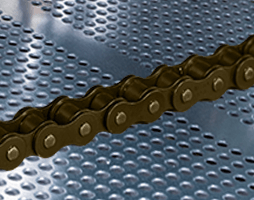

Offset sidebar chains

Rotary chains, also known as offset sidebar chains, are widely used in drives with high power and low rpm.

As the chain exclusively consists of the same links, there is a stable and homogeneous drive torque. The wear pattern in each hinged part is also identical, unlike with a normal chain which has inner and outer links.

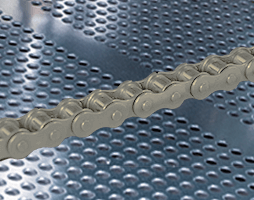

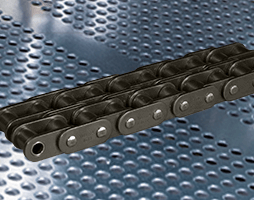

Roller chain

Roller chains according to ISO 606 for machine and plant industry

Roller chains are frequently used in machine and plant industry, not only as drive and gear chains, but also as lantern gears, hoisting and conveyor chains as well as in special designs with different attachments for transport and conveyance systems. Roller chains with suitable attachment allow for special functionalities and are thus perfect for a wide range of different applications.

Advantages of roller chains

- wide application range as drive, conveyor and hoisting chains

- miscellaneous functions by means of attachments on special chains

- robustness to temperature influences and soiling

- positive-locking transmission without slip

- cost effectiveness

- excellent application range due to different chain sizes, simplex and multiplex chains

- manifold transmission ratios

- long shaft distances possible, e.g. for conveyance systems

- life cycle limit indicated by chain elongation

- problem-free shortening and lengthening of chains

- drive possible on either side

- no pre-tensioning required = low static bearing load

Product range

- roller chains European type (ISO 606)

- roller chains American type (ISO 606)

- roller chains type series GL with straight plates

- roller chains type series RF made of stainless and acid-resistant steel

- maintenance-free roller chains Marathon and Marathon stainless

- low maintenance roller chains Biathlon and Biathlon KS

- roller chains made to customers’ specifications

- roller chains with attachments

- double pitch roller chains (ISO 1275)

- power chains type series HX

- special heavy duty chains

- roller chains according to works standard specification

Effective coating for optimal corrosion protection and wear resistance

Functional coatings considerably extend the application limits of roller chains. Depending on the respective requirements, chain components can be chemically nickel-plated, galvanized or coated with a zinc-flake layer to significantly improve corrosion protection. In order to increase wear resistance, we have the possibility to chemically nickel-plate, nitrate or borate the chain pins.Roller chains made of stainless and acid-resistant steel are particularly suitable for drives susceptible to corrosion as well as for extremely high and low temperatures. Therefore they are mainly used in the chemical as well as in the food and beverage industry.

The different types of roller chains comprise double pitch roller chains according to ISO 1275, the roller chains type series GL with straight plates for conveyance systems, and power chains based on roller chains according to ISO 606 for higher requirements as to breaking load and fatigue resistance. Roller chains according to works standard specification complete our range of standard chains with regard to dimensions or transmissible power.

Technical product information:

Corrosion resistance

Corrosion resistant chains are made of either corrosion-resistant materials or they are steel chains that are treated with a special coating.

For more information, read the options mentioned in nickel-plated, zinc-plated or stainless steel. In addition, lubricating the chain is another (limited) method of preventing or reducing corrosion.

Galle chains

A Galle chain is the simplest type of steel link chain.

Galle chains were named after their inventor André Galle (1761-1841). A Galle chain is the simplest type of steel link chain. The plates rotate directly on the pin lug. With this type of chain the bearing area is

very small. Therefore the chain speed should not exceed 0,3 m/s. Consequently, Galle chains are less suitable for power transmission, and they are almost exclusively used as load chains (e.g. counterweight chains, lock chains and

tack chains).

Straight plates

Roller chains with straight plates are capable of sliding or carrying over a conductor a load that is pressing directly on the plates.

The advantage is that the surface pressure is distributed over a larger surface, resulting in less wear and tear on the link plates and the conductor. K&W Transmissies supplies these chains (DIN 8187, DIN 8188) in various qualities from different brands, in stainless steel, nickel-plated or zinc-plated versions. They are also available with attachments and/or extended pins or with POM nylon clips.

Technical product information:

Stainless steel chains

Stainless steel chains are used in humid environments and where corrosion is undesirable

Stainless steel chains are used in humid environments and where corrosion is undesirable, for example in the food industry. These chains are manufactured from stainless and acid-resistant steels. However, stainless steel chains have a lower tensile strength than steel chains.

The stainless steel chains of the DINN brand are supplied standard without lubrication, giving the customer the ability to customize the type of lubrication to the conditions and requirements under which the chain is applied.

Technical product information:

Wippermann

Marathon

Stainless steel

NEWS

-

01 Mar 2025

-

02 Feb 2025

-

03 Jan 2025

-

11 Jul 2024

-

02 Jun 2024

-

26 Mar 2023

Careers

QUOTES

From a sustainable energy company in North Holland

For some years now we have been purchasing various products from K&W Transmissies, which we as end users have profited from considerably. In particular, we appreciate the company’s commitment, its guidance and its excellent service, all of which have ensured the development of a pleasant cooperation.

Jimmy