workshop

WORKSHOP

WORKSHOP

Workshop

Own workshop

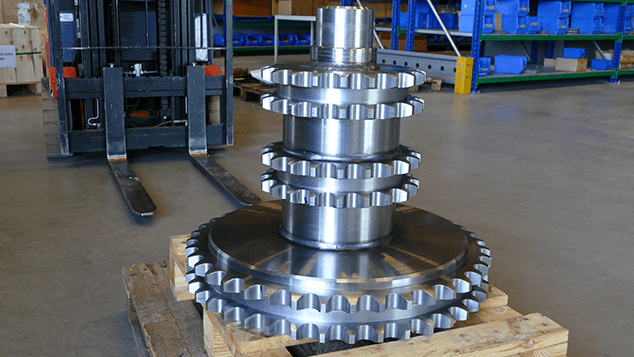

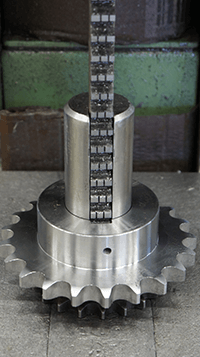

What do we make? We make our own perfect sprockets in our sprocket factory right here in Lelystad! We have been doing this for two decades with a lot of dedication and a strong team of ten employees. A small number of items or different models and materials are not a problem for us at all.

“BRING US THE CHALLENGE AND WE’LL SINK OUR TEETH INTO IT!”

OWN PRODUCTION FACILITIES ON SITE

K&W Transmissies also produces completely custom-made sprockets from solid material according to customer-specific drawings. K&W Transmissies stands for customization and complete control of quality and delivery times. To achieve this, K&W Transmissies has its own production facilities. High-quality technological equipment and machinery are used to manufacture custom-made wheels from raw material or for the modification of semi-finished products. Sprockets can be produced in various designs of high-grade types of steel, but also of plastic or stainless steel. The sprockets can also be produced with hardened teeth, a protective layer of zinc or chemically blacked.

VARIOUS TYPES

Sprockets that are used for roller chains or conveyor chains have their own type of toothing. Moreover, sprockets for round link chains or drop forged chains must meet very specific requirements. Each sprocket has its own type of toothing adapted to the character of the chain. K&W Transmissies has extensive knowledge and experience in producing sprockets that are optimally adapted to the demands placed upon them.

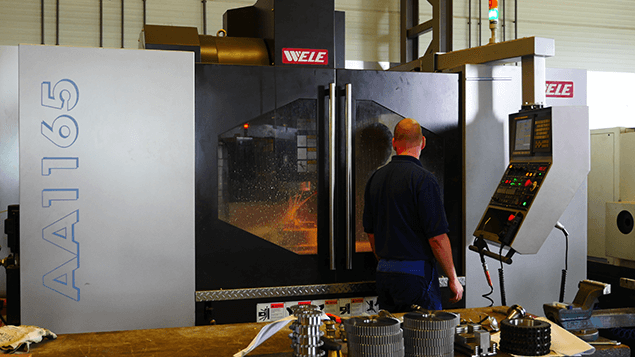

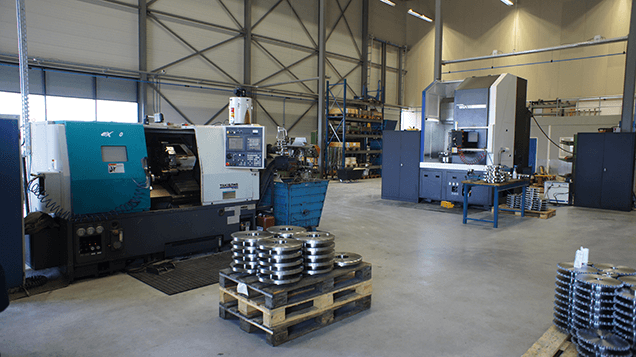

MODERN EQUIPMENT AND MACHINERY

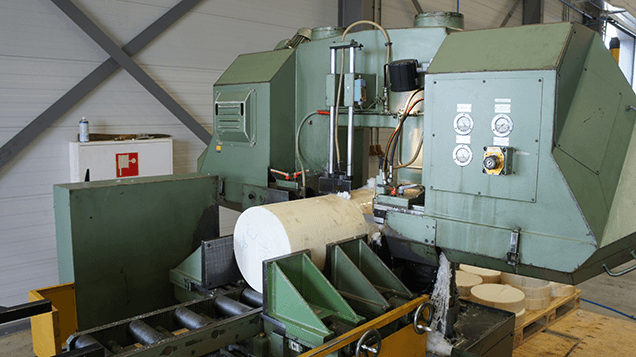

Our equipment is fully and optimally designed for the production of sprockets. Multiple fully automatic saw benches, especially equipped welding line with welding manipulators, a section with conventional and CNC lathes, a special division with modern CNC milling machines and a department with different broaching, boring and tapping machines.

Modern CNC machines

- Sawing

The basic material for the production of sprockets is cut from round bar stock using our own saw machines. For larger diameters, the material is usually purchased as discs.

- Lathing

The sprocket is lathed from solid material or from a welded construction, depending on the prescribed specifications. This is done on several high-end horizontal and vertical CNC lathes.

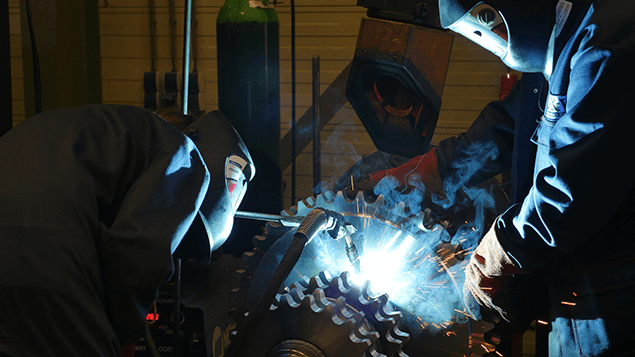

- Welding

A hub is adapted using a welding manipulator for optimum quality of the weld. This ensures the strength of the bond.

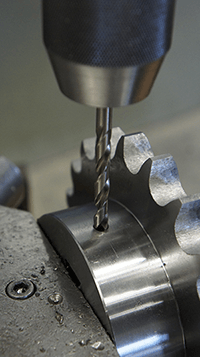

- Toothing

The tooth shape in particular can be adapted to the requirements that are set by the sprocket. K&W Transmissies has developed its own special CAD/CAM software, which can efficiently set the parameters for the desired tooth shape. Toothing can be done through contour milling on a machining center or with special hobbing.

Sawing

Lathing

Milling

Welding

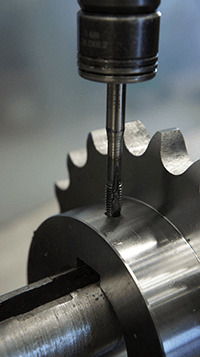

- Broaching, boring and tapping

Usually, bores are provided with a keyway and a threaded hole so that the sprocket can be fixed on the shaft. Keyways are broached with different tolerances. Multiple keyways can also be made at a specific angle.

Broaching

Boring

Tapping

PROCESSING OF SEMI-FINISHED PRODUCTS

K &Transmissies has a very large stock of standard sprockets and gears. These can quickly and efficiently be provided with a boring and keyway so they can be mounted directly upon delivery.

EXPRESS OPERATIONS

In consultation with the sales department, delivery times of 1 to 3 days are possible.